Marine Systems

Gravity Self-Unloader

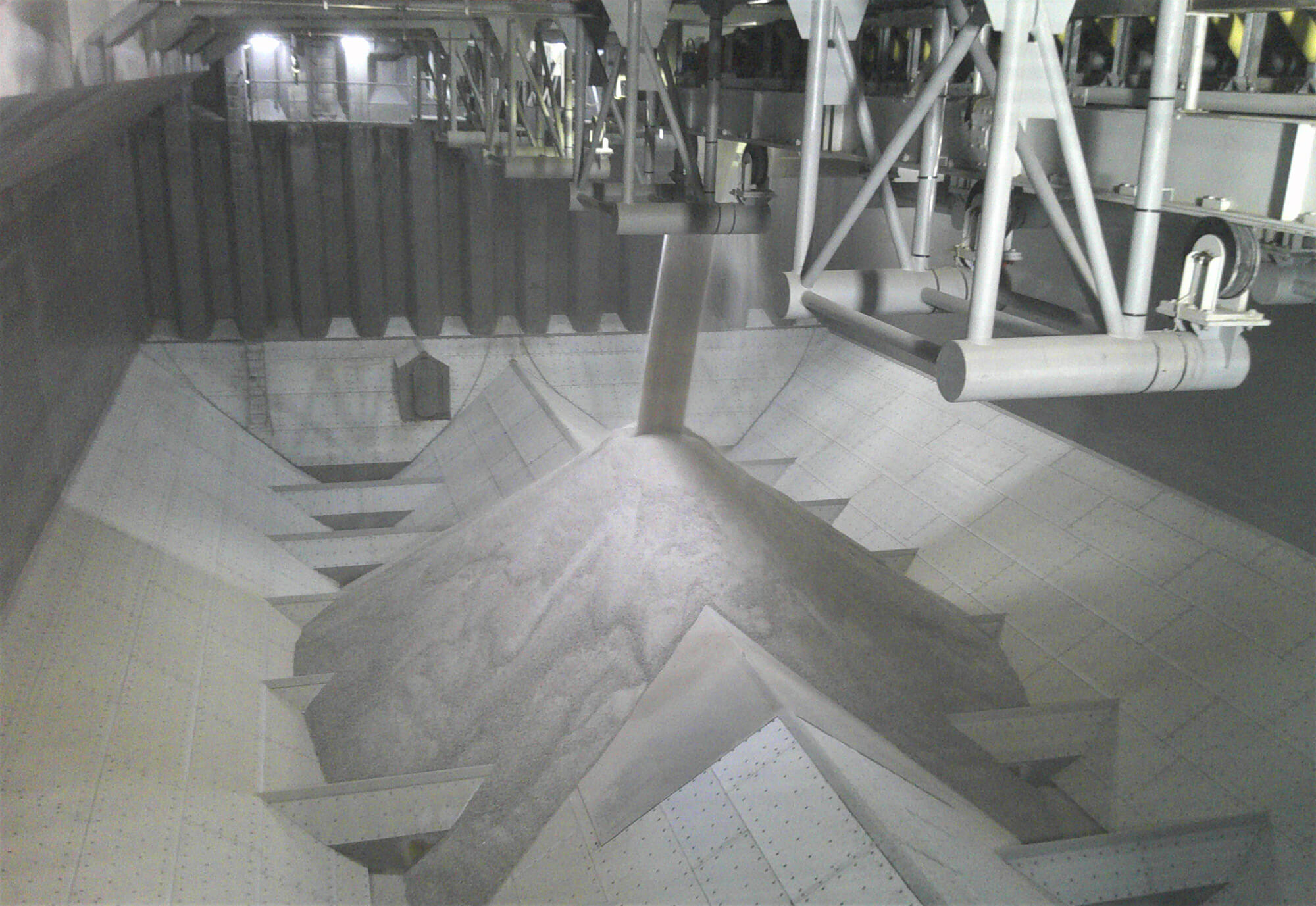

Gravity self-unloaders are the most common type of self-unloader. It uses gravity to release material through the gates located at the bottom of the cargo holds onto conveyor belts running beneath the cargo area. Next, the material is transported to an elevating system, lifted above deck level, and transferred onto a discharge boom conveyor. It is then offloaded via the discharge boom, port or starboard, depending on the unloading facility or vessel arrangement.

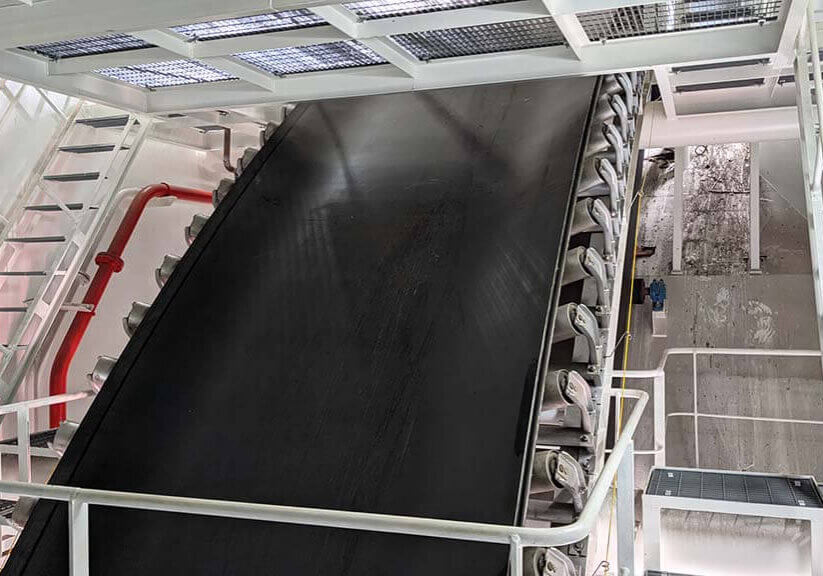

Innovative designs such as the EMS-Tech Feeder Gates, sandwich belt conveyors which are commonly known as ‘C’ Loop or ‘S’ Loop conveyors, incline belt conveyors, pocket belt systems, and or bucket elevators are all common arrangements to be used on self-unloaders. The ‘C’ Loop conveyor is the most common type of elevating conveyor.

EMS-Tech is the leading provider of gravity self-unloaders worldwide and can design systems to handle a wide variety of dry-bulk materials at rates greater than 10,000 tons per hour.

Mechanical Reclaim Self-Unloaders

EMS-Tech offers multiple options for Mechanical Reclaim systems:

Scraper arrangements utilize a rail-mounted gantry scraper arm which ultimately pushes material forward or aft to the elevating conveyor. This arrangement is limited to only a few materials and is suited for lower discharge rates.

Bucketwheel Reclaimers utilize a rail-mounted bucketwheel bridge reclaimer capable of traversing the length and width of the cargo hold. These types of arrangements can handle different materials with varying discharge rates.

Reclaimer Scraper Arms utilize a rail-mounted reclaiming arm with a series of specialty buckets to lift the material onto the belt conveyor installed on the reclaiming bridge, which feeds the material to the outgoing conveyors. This type of arrangement can traverse the length and width of the cargo hold and is suitable for sticky materials and lower discharge rates.

Hybrid Self-Unloaders

Hybrid Self-Unloaders are well-suited to self-load and carry out offshore transhipment operations. Hybrid self-unloading systems use a mechanism, usually grab cranes to raise the material and deposit it into a hopper onboard the deck of the vessel and then transferred to a series of deck-mounted conveyors to a fixed length or traveling boom conveyor.

Transhipment Systems

Transhipment systems transfer material to barges or ocean-going vessels. These systems are ideal for smaller vessels or barges with shallow draft to transfer material from shore to an ocean-going export vessel stationed offshore. Transhipment solutions are becoming increasingly popular in high-growth emerging markets because it allows the miner to move their product with minimal port infrastructure upgrades required.

Single Point Loading Systems

Single point loading systems can be introduced into a variety of vessel arrangements. The ability for a vessel or barge to self-load using a material handling system eliminates the need for the vessel or barge to shift during loading, which improves the efficiency of cargo operations and the safety of ship and shore personnel. By introducing a single point loading system, you can also reduce your shore side infrastructure costs with a simple loading boom arrangement.

Advantages of our Marine Systems

Key Features of our Self-unloaders

EMS-Tech Gate Feeder

- Ideal for gravity self-unloaders and difficult cargoes

- Reduced dusting

- No skirting or spillage

- Replaces more costly and complex belt feeders and vibrating feeders

‘C’ Loop Elevating Conveyor

- The ‘C’ Loop Elevating conveyor uses two conveyor belts, face-to-face, to contain the product being carried, allowing for a vertical lift of material from the cargo hold

- Provides a reduced footprint

- Cost-effective and highly efficient

Discharge Boom Conveyor

- The boom conveyor discharges the material to the shoreside or shipside receiving facility

- Can be fixed in length and range from very short to very long

- The largest fixed length boom delivered by EMS-Tech is 90.5meters and capable of unloading at a rate of 5,500mtph

- Shuttling features allow for various types of unloading and trimming capabilities